Airjet Exciter System for the High Cycle Fatigue Testing of Gas Turbine Blades

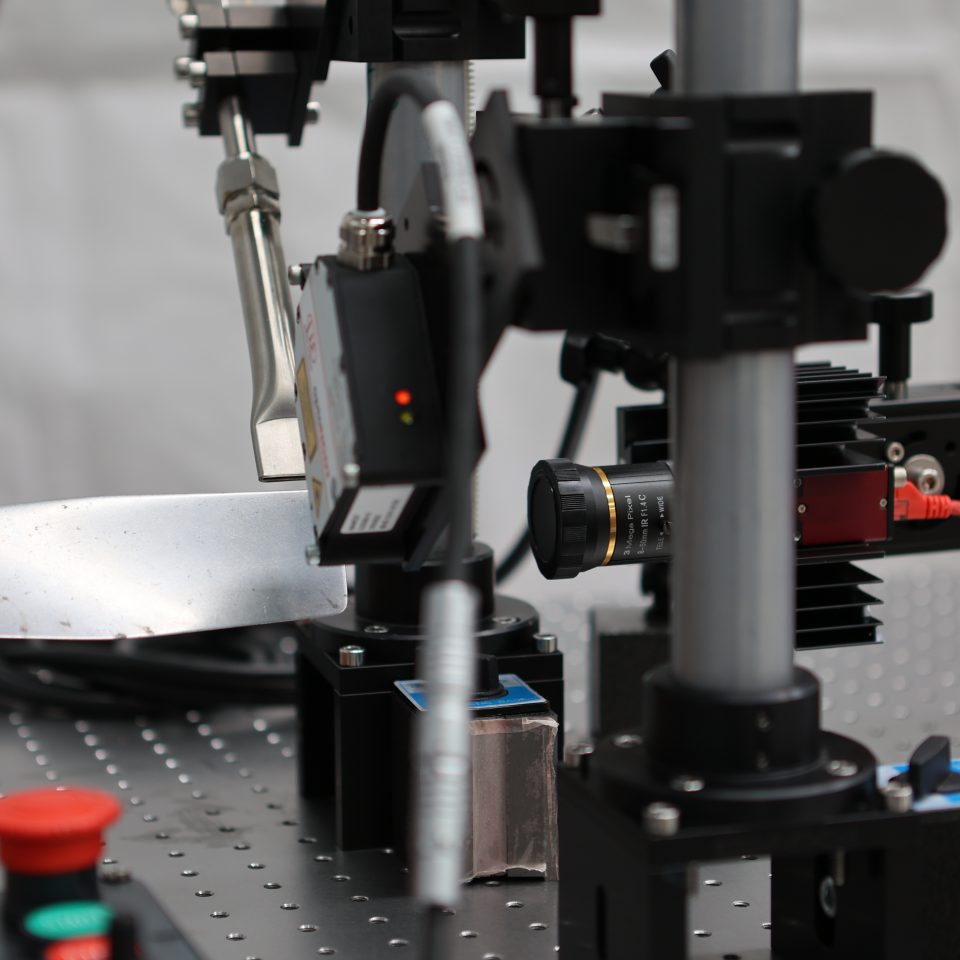

SCITEK’s Airjet Exciter facility consists of an optical system that is used to dynamically measure the amplitude of oscillation of the component whilst other sensors like a microphone or an optical triangulation probe or a laser vibrometer can be used to measure the component frequency of oscillation.

The system also makes use of a jet of compressed air to excite the blade and maintain the amplitude of oscillation at a constant level. The system is connected to a windows based PC which provides the main control operations and the main user interface to facilitate carrying out and monitoring progress of a test. The PC also records all necessary data during the test and at the end of the test produces a report that us used to document the test.

Components of the facility

- Networked PC (PC or Laptop) with the SCITEK Airjet Excitation software installed.

- Airjet Excitation Control Unit with Manual Control pendant.

- Two GIGE cameras with high magnification lenses

- Two 3D manual traversing gear to allow easy adjustment of cameras

- Hydraulic blade camping mechanism to suit customer blade shape

- High flow rate pressure regulator and airjet nozzle – custom made to suit customer requirements

- Microphone or other frequency measurement device to suit customer requirements.