About Image Analysis

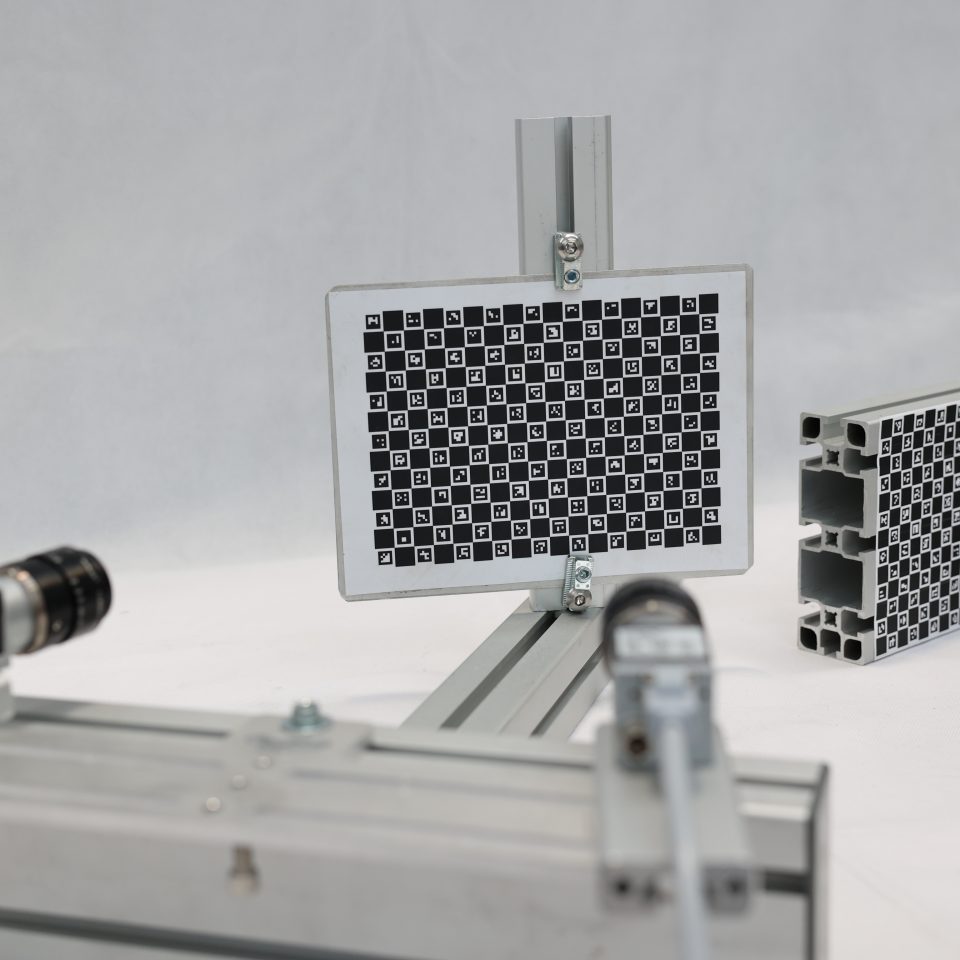

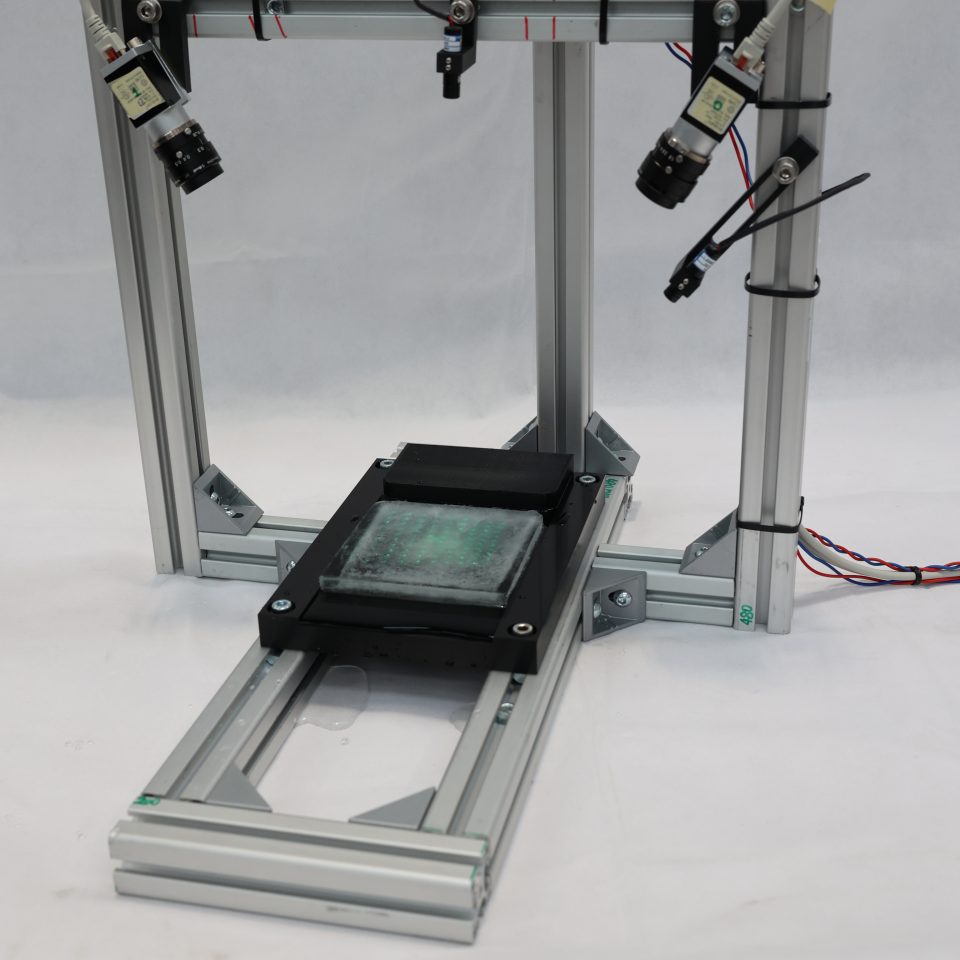

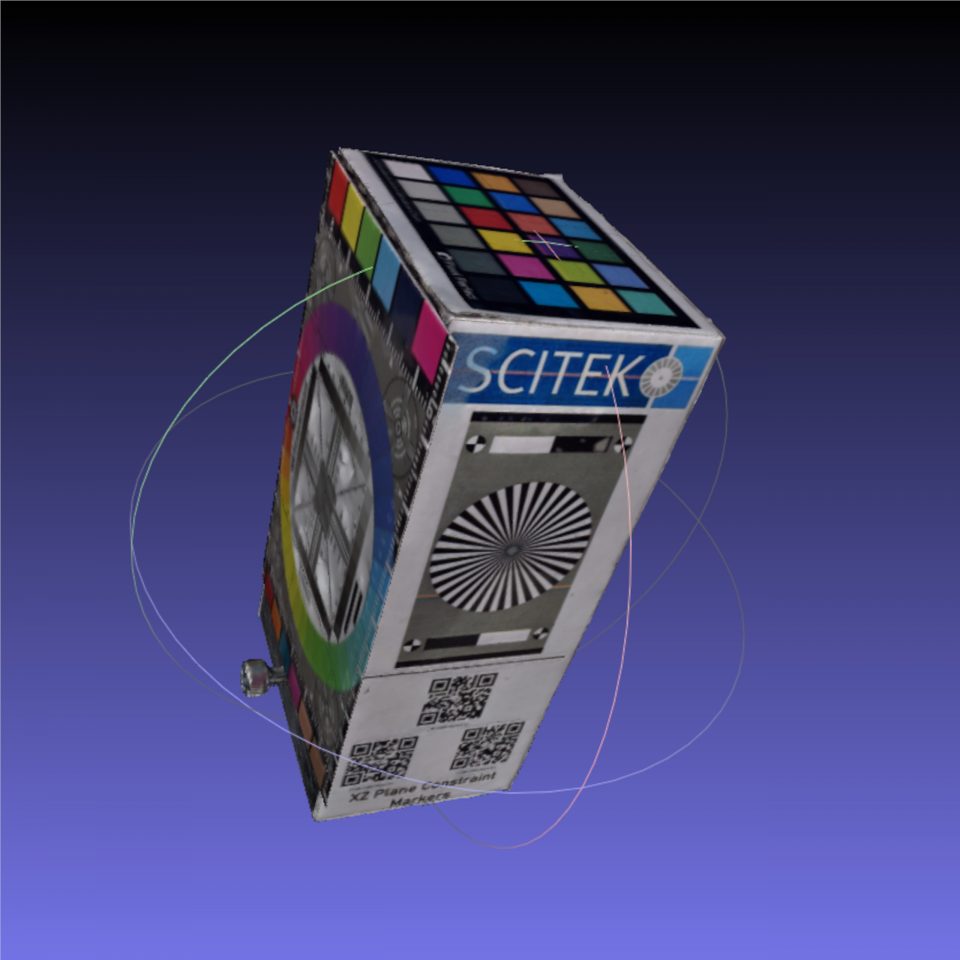

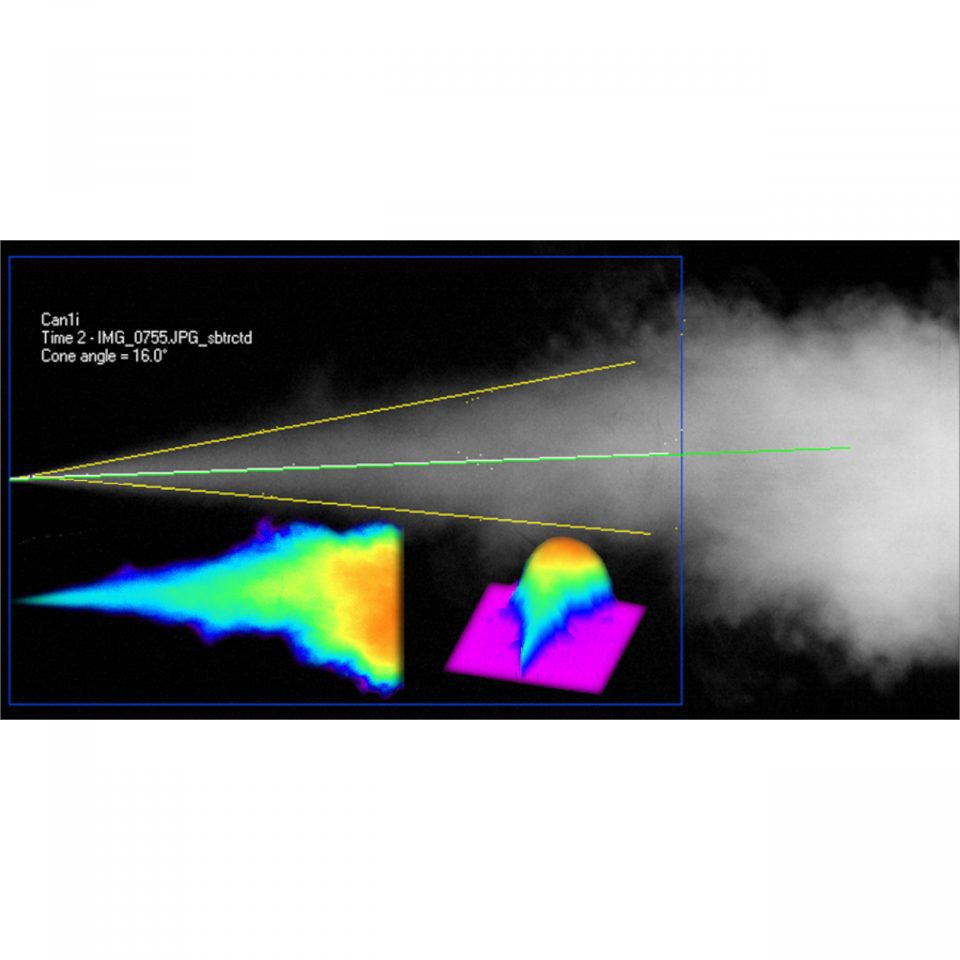

Vision based solutions gather information about an object or environment using images. These images are optimised and processed using a variety of techniques and algorithms to solve a particular challenge. This challenge may require a combination of visual inspection, detection, measurement, pattern recognition, 3D reconstruction, and/or reverse engineering.

With our dedicated Labs and test facilities we provide services in imaging and vision experimentation. We design and manufacture rigs, develop experimental methods, perform the experiments as well as process & analyse data, draw conclusions and make recommendations. A full turnkey solution.

Example Projects:

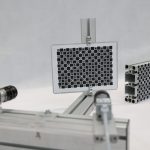

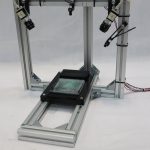

- Particle volume measurement on magnetic chip detector using structured light and laser triangulation systems.

- Vibration amplitude for fatigue life estimates of aero-engine blades including real-time video processing.

- Thermal Imaging for temperature assessment of frictional wear on aero-engine component interfaces.

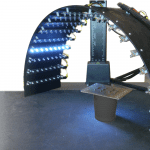

- Metrological diametrical and position measurements on holes in aero-engine combustor components using computer vision techniques.

- Neutron beam imaging in applications of CT scanning for 3D reconstruction

- Development of automated inspection software of aero-engine components for damage detection and measurement.

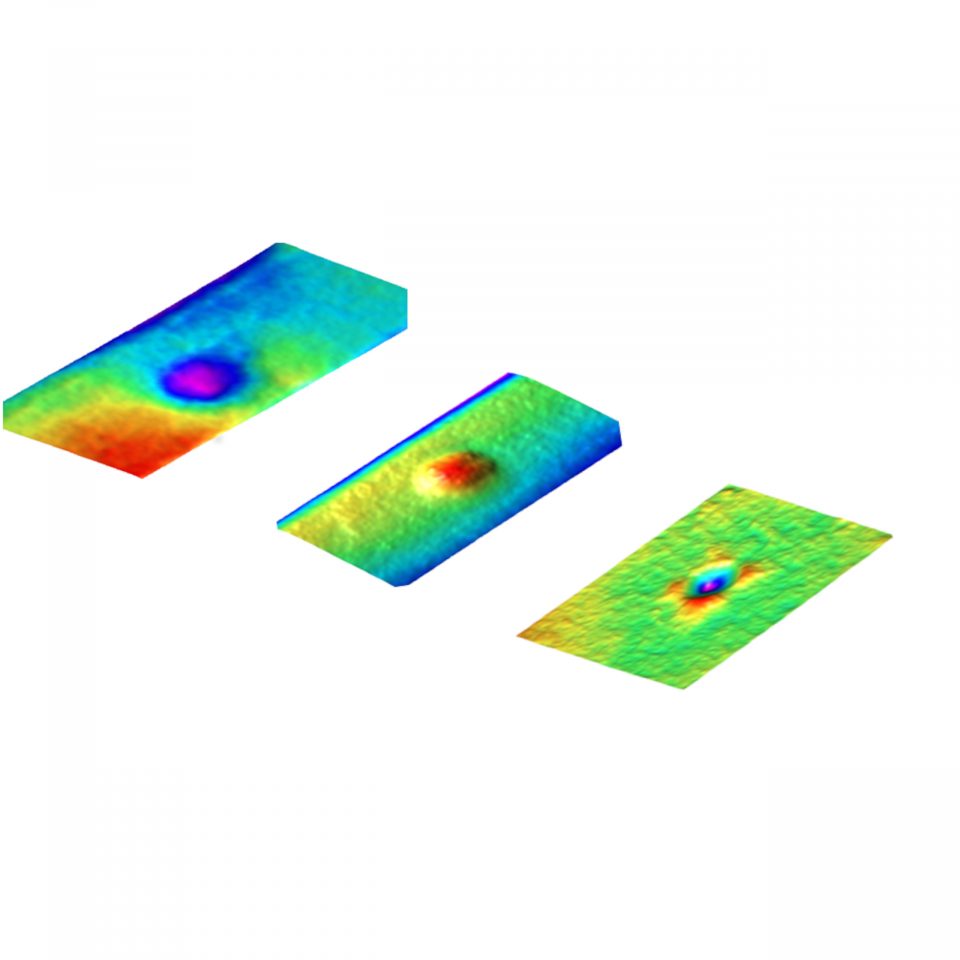

- Topographic severity system using photo-metric stereo technique for aero-engine component assessment.

- Automated photography station to capture surface features, textures and colours of components. Built-in 2D and 3D image analysis software generates a database of digitised life-cycle data for enhanced through-life engineering.