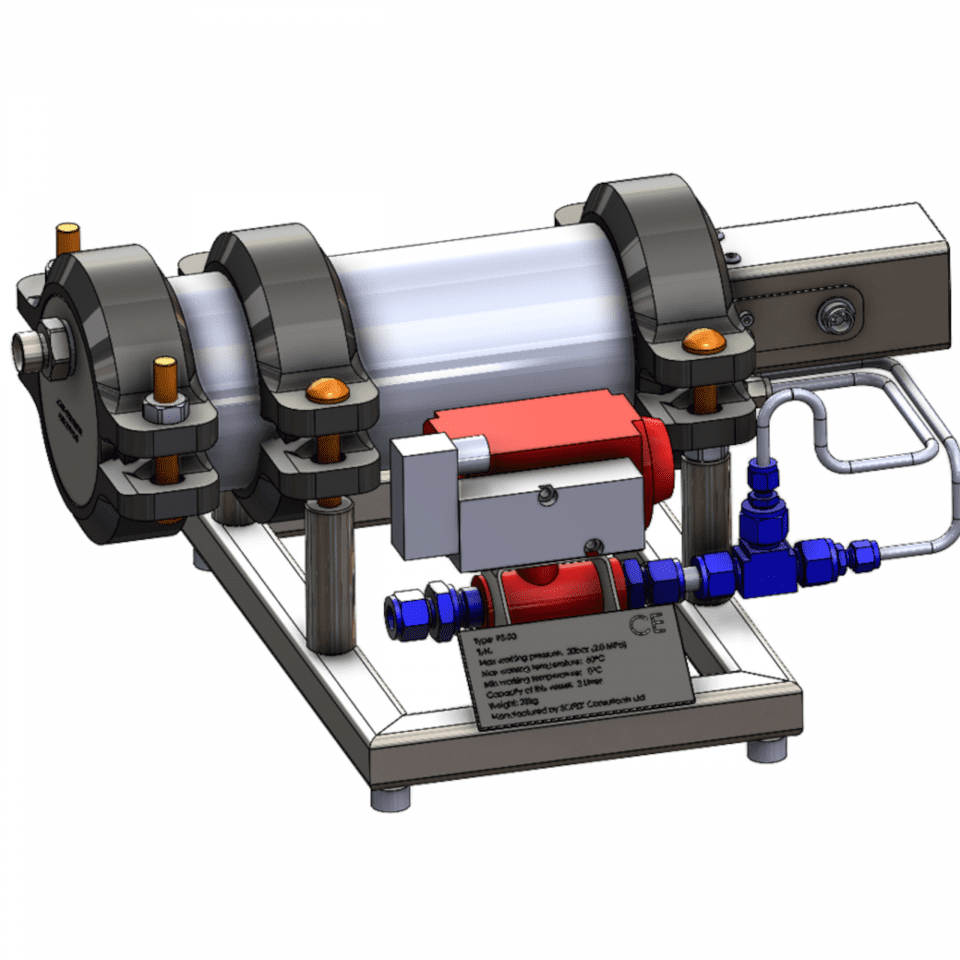

PS-10 & 20 Remote Operation Powder Seeder

Dantec Dynamics are acting as agents for our powder seeders. For details and pricing please refer to the Dantec Dynamics web page, model number 10F01.

The PS-10 and PS-20 powder seeders are operationally equivalent, with the PS-10 seeder rated to a working pressure of 10 bar and the PS-20 seeder rated to 20 bar.

Specification

- Up to 10 or 20 bar working back-pressure (PS-10 and PS20 respectively).

- Controllable seeding density.

- Dilution air available.

- Stainless steel pressure vessel construction.

- Remote Panel Controls – Electrically operated rate of powder dispersal and thus seed density. Pressure regulator to adjust air supply to seeder. Two pressure gauges to indicate air supply pressure and seeder back pressure. Compatible with solenoid valves for PLC or computer control.

- Push-fit pipe connectors and colour coded air tubes for easy installation and adjustment of remote cable length.

- Suitable for a variety of powders and particle sizes. Aluminium oxide or Titanium Dioxide powders are recommended. This seeder was specifically developed for LDA and PIV applications where small particle grain powders need to be used. For LDA applications it is recommended to use Aluminium Oxide powder of 0.3um size, available from us, or from metal polishing suppliers.

- Maximum duration for continuous powder delivery is 30 minutes. A second powder container drum is provided for quick change-over.

- Remote control panel enables the powder feed to be switched off when not needed thus extending the period between re-fills and minimising the quantity of powder used.

- Quick re-fill operation without the need to stop experiment.

- Controllability of seeder can be customised to suit other user requirements.

Performance

The biggest problem with other powder seeders is the break up of the powder to the smallest grain size. With grain sizes below 1um particles tend to agglomerate and unless are broken up by the seeder their ability to follow the flow is reduced. The Scitek PS-10 seeder employs sonic jets which create high shear flow fields which break up the powder while is being dispensed in the outlet chamber. The seeder was tested against an oil mist generator in a supersonic wind tunnel and measurements were made of the response of the particles along a normal shock wave using a Laser Anemometer operated in back-scatter. Aluminium Oxide powder with 0.3um size particles was used. As can be seen in figure 1 there is excellent agreement in the results obtained with the two types of seeding devices. The design of this seeder is such that clogging experienced by other powder seeders is inherently avoided. Our proprietary powder dispensing method also ensures uniform seeding density during operation.

Recommended Powders

Aluminium Oxide powders 0.3 microns in size or higher can be used and they are available from ourselves or from metal polishing suppliers. This unit was specifically designed for small size powders that do not flow readily. However, powders of larger grain size tend to flow more readily and can also be used.