The Solution

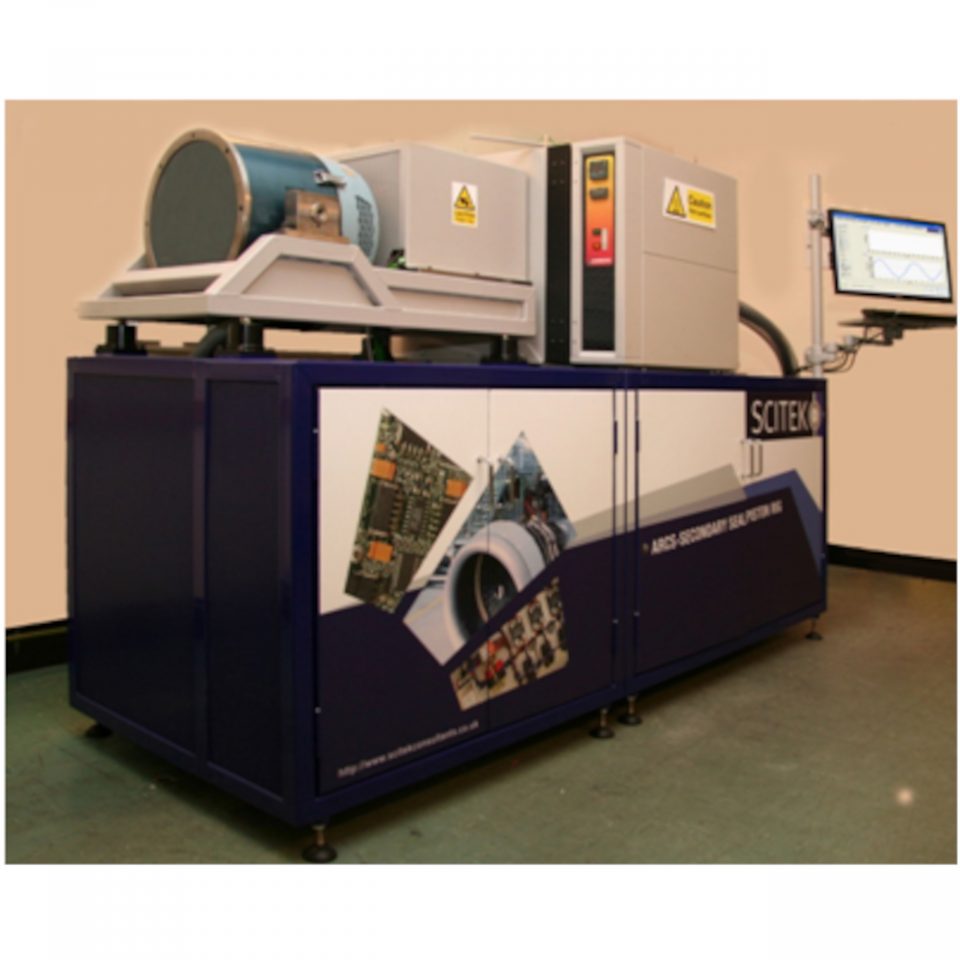

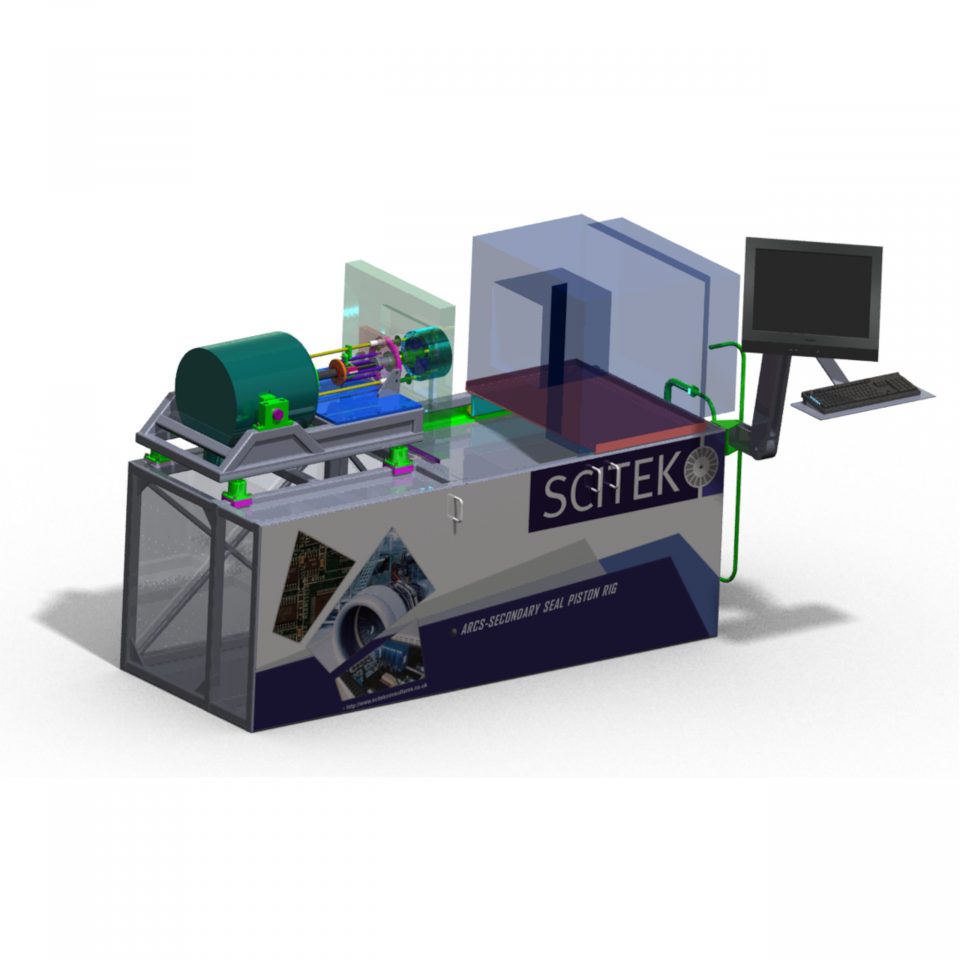

SCITEK Consultants Ltd. designed, manufactured and commissioned a robust mechanical test rig that was capable of reproducing application specific movements under a representative pressure and temperature envelope. SCITEK also developed the control and acquisition system. A desktop PC was used for managing the test schedule and storing of test data.

A servo-motor driven lead screw assembly was used to facilitate large axial movements and a shaker to superimpose small high frequency movements. A cRIO 9074 system was finally used as the main control system allowing real-time signal processing and adaptive control of process variables.

The system developed was capable of cycling the seals within the range of mechanical and thermal envelope fully representative of the application operating conditions.

About the Project

Rig Overview

The rig frame was made out of steel box section that was stiffened to ensure that its natural vibration frequencies were well outside the operating frequencies specified in the seal test schedule. An air cooled shaker was used to produce small high frequency movements (0.1mm at up to 200Hz) operating under closed loop control and a servo motor lead screw assembly was used to produce large axial movements of up to +/-6mm.

The piston, cylinder and seals under test were housed in an environmental chamber capable of maintaining setpoint test temperatures in the range of -50°C to 300 °C. Liquid Nitrogen was used to achieve temperatures below ambient.