The Solution

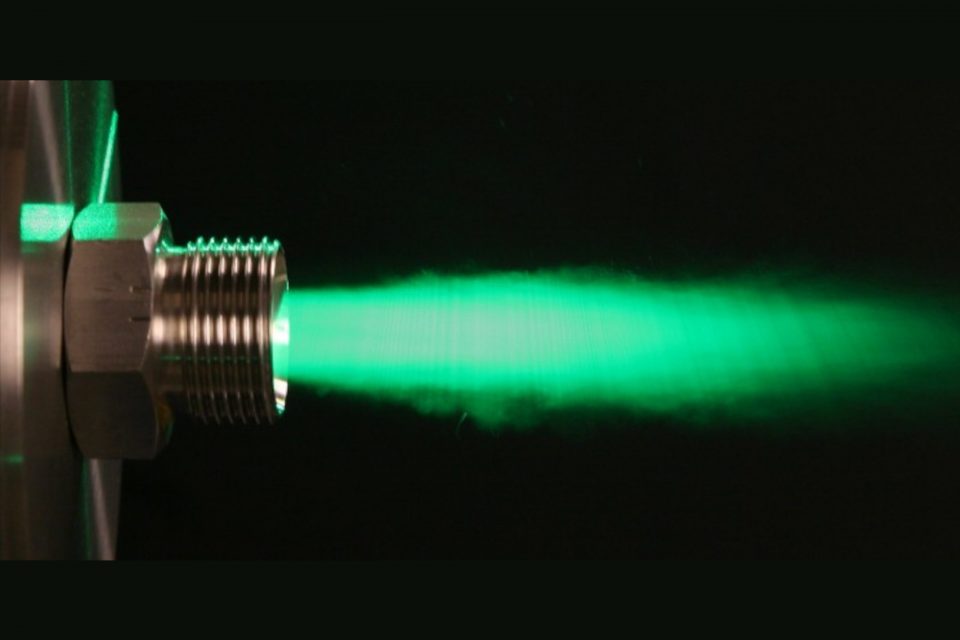

The SCITEK system solves these problems by making use of larger particles (1 to 6 microns) using high-pressure atomising nozzles. An additional advantage is that these nozzles deliver very large quantities of seeding particles (1010 particles per second). Also by using more than one nozzle the seeding can not only be spread over a large area but can also be designed to produce high data rates, which reduce the time it takes to complete the experiment and thus helps reduce costs. For large, aerospace type, wind tunnels the saving from reduced running time helps recover the cost of the seeding system in just a few runs.

About the Project

Previous Applications

SCITEK high pressure wind tunnel seeding systems have been supplied in the UK to Airbus, the 8×8 feet DERA Bedford supersonic wind tunnel, and to Loughborough University for their low speed wind tunnel. A number of such systems have also been sold to various Universities in Brazil, USA and in Norway. Our seeder has also been used successfully in supersonic blow down tunnels in the UK and Germany.

Particle Size Issues

The SCITEK system solves these problems by making use of larger particles (1 to 6 microns) using high-pressure atomising nozzles. An additional advantage is that these nozzles deliver very large quantities of seeding particles (1010 particles per second). Also by using more than one nozzle the seeding can not only be spread over a large area but can also be designed to produce high data rates, which reduce the time it takes to complete the experiment and thus helps reduce costs. For large, aerospace type, wind tunnels the saving from reduced running time helps recover the cost of the seeding system in just a few runs.

Implementation in Large Wind-Tunnels

In large wind tunnels the use of this seeder is quite complex and normally comprises of three separate components each installed in a different part of the wind tunnel. These components are the “seeder skid” normally located outside the seeding rakes (usually four) that are installed inside the wind tunnel upstream of the working section, and finally the control panel that allows operation of the seeder from the wind tunnel control.

Seeder Skid

The seeder skid is a purpose made enclosure with two separate compartments which are accessed by two sets of doors. The first compartment houses all electrical and compressed air components and the second compartment houses all components that get wetted with water such as all pipe work, pump, valves etc. For safety the compartments are separated by a steel plate so that if a water leak develops in the compartment with all the pipes it cannot find its way to the electrical side and cause an electrical short.

A 3 phase 3.3KW electric motor is used to drive the high pressure water pump. and has a maximum speed of 1500rpm. During operation the speed of the motor and pump is varied by the remote control unit to match the water flow to what is demanded by the rakes that are active. This is automatic and no user adjustment is necessary.

On entry to the skid the water goes through a manual on/off valve and then through three filters housed in series to remove any debris that may be in the water supply and to ensure that the spray nozzle do not become blocked.

The water then passes through a UV steriliser which should kill any bacteria that may be in the water. The pump then pressurises the water which passes through two sintered metal filters before finding its way to the seeding rakes via pneumatically operated valves. The two Sintered metal filter units are arranged in parallel to reduce the risk of blockage. These filters are more effective than the low pressure filters.

A series of valves are also installed to facilitate an air purge and water purge functionality. The air purge allows the seeding rakes to be purged with compressed air at the end of a test in order to empty the water from the pipes and spray nozzles. The same valves will also allow for the pipes and nozzles to be flushed with fresh water when it is to be used after long periods of inactivity so that any residual stagnant water that was not cleared during the air purge operation is flushed to the drain. The UV steriliser, the air purge and water flush facilities are to ensure that the seeder minimises health and safety hazards associated with spraying stagnant water.

Seeding Rakes

In order to ensure that the wind tunnel is uniformly seeded the spray nozzles are spread over an area so that the seeding can spread uniformly within the measurement region of the tunnel. The nozzles are also divided in to four rakes so that the operator has the flexibility to choose which rake is active so that the amount of water sprayed in to the wind tunnel is minimised.

Control Panel

The seeder control unit is a wall mounted cabinet that is normally installed in the tunnel control room. Features include varying which rakes are active and also displays the water atomising pressure. It also includes air purge and water purge facilities. At the hard of the control system is a microprocessor controller that can operate on all pneumatic valves and via the buttons on the front panel it can activate the various functions via fail safe logic control so that if for example the supply of water or air are not connected the seeder cannot be turned on as this will cause damage to the pump.