The Solution

A CFD optimised, water cooled probe with thermal barrier coating made from Stainless steel.

SCITEK designed, analysed and manufactured the bespoke probe. The main body was made from a single piece of material and the internal passages were created with the use of deep hole gun drilling and EDM wire erosion.

About the Project

By using commercially available materials, the project cost and lead time could be kept down to meet the customers test requirements.

The material selection was only one of the challenges for this project. The manufacturing method would also require novel thinking and the use of more specialist subcontract manufacturing.

When producing probes that see localised high temperature cycling, standard welded fabrications often result in failure. On this probe the logical method would be to weld the probe from several parts to produce an internal water jacket. This would require welded joints close to the regions of peak stress on the probe.

Therefore this project was approached with the mind-set to use as few components as possible. Our CAD system allows us to rapidly visualise various design concepts, but turning these into a solution that can be machined, requires manufacturing knowledge and a wealth of experience. SCITEK marry these skills and knowledge to achieve innovative solutions.

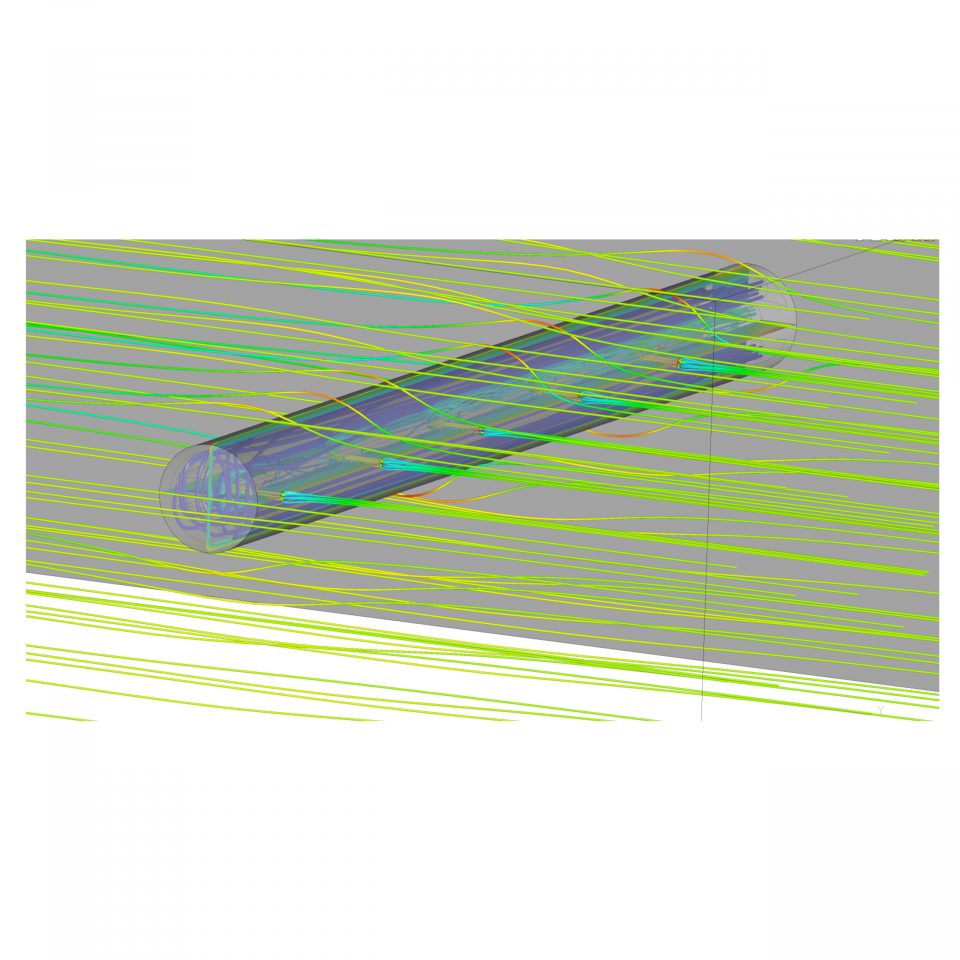

Using CFD modelling our analysis department determined and optimised the water cooling efficiency of the probe and assessed the effectiveness of the thermal barrier coating. The structural integrity of the probe was also substantiated for the aerodynamic loading of the hot exhaust flow.

The main probe body on this project consisted of a single machined body which only required welding at either end to plug the air and water passages and an end-cap to direct the water around the probe tip. This kept all welding away from the high stressed region.

The internal passages for taking the gas sample and provide the water cooling jacket, were created with the use of deep hole gun drilling and EDM wire erosion.

Finally, thermal barrier coating was applied to reduce the heat transfer from the combustion environment into the probe material.